Reader's Choice

Popular articles

Microfiber or microfiber is a fabric made of thin synthetic filaments of various polymers (plastic materials). She received her micro prefix because of the thickness of fibers no larger than 1 denier (1 gram per 9 kilometers).

These raw materials are used in the textile industry for the manufacture of woven, non-woven and knitted fabrics, as well as in industrial filters and in the manufacture of products for cleaning.

A modern microfiber thread having a length of 100,000 meters will weigh only 6 grams. But its production is very difficult, for this special machines were invented - extruderswhich soften the blank base and give it the desired configuration by punching through the core shape with the thinnest holes. At the end of the process, the thread is cooled and sent to the plants.

The production of microniths began in 1950 using the method of twisting the molten masses, but the Japanese started the production in 1976.

Microfiber cloth is indispensable in the manufacture of special-purpose clothing (sports, tourist, military) and materials for cleaning. She possesses following important qualities:

Thus, microfiber items do not disturb the heat exchange during increased physical exertion or stay in extreme conditions, but on the contrary, perfectly remove excess moisture, allowing the body to breathe and not freeze. At the same time, they weigh very little, putting such a jacket in a heavy backpack, you will hardly notice its weight.

There are practically no drawbacks, only one - with the accumulation of a large amount of moisture or fat, the absorption capacity is completely lost. But this can be corrected by good washing and drying, only without using iron or other heating devices.

It is necessary to dry such material in a natural way, otherwise it will irrevocably deteriorate.

In addition, recently began to produce bedding of this material, and it is not inferior in quality silk or cotton, as it has the following advantages:

And disadvantages:

There is another drawback, often unscrupulous manufacturers try to make linen cheaper by using low-quality raw materials and pass it off as expensive microfiber. Carefully choose accessories, pay attention to seams, uneven pattern and sharp chemical smell.

For cleaning this material is suitable and machine washable and hand. If you choose a typewriter, the temperature regime is suitable medium - 40-60 degrees.

The main thing, give up on:

There are also no special requirements for hand washing:

When things are very dirty, do this:

The choice of materials today is huge and people already doubt which thing is better to buy, for example, from microfiber or polyester? To do this, you must clearly understand what is what. With microfiber, everything is already clear, let's deal with polyester.

Polyester - synthetic material derived from petroleum products, which are processed by high temperatures, pressed through special machines, cooled and twisted into thin threads.

In appearance, they are similar to wool, and on the properties of cotton. Polyester has many qualities of microfiber (not crushed, durable, does not stretch), but its threads are thicker, they practically do not let air and water through.

Thus, if you need a jacket capable of protecting from wind and rain, to keep warm - a polyester product will do. If it is clothing that you will use when playing sports - take a microfiber.

Of the disadvantages of polyester should be highlighted:

It becomes clear that there can not be a fabric one better than another, just each has its own purpose, which must be understood.

So, we told where microfiber is used, what kind of fabric, what properties it has. This material is very popular today, but sometimes other synthetic substitutes are sold instead. So remember, real microfiber cannot cost too much.

In this video, Andrei Makarov will tell you what characteristics microfiber cloth has, will conduct a comparative review of towels made from this material:

Innovative microfiber fiber material used in the manufacture of home textiles. It received its name due to the thickness of the fibers included in its composition.

Material properties

Microfiber is a fabric that looks like natural suede, but it is made from polyester and can be both woven and knitted. Its distinctive features:

Use of products

From this material it turns out a very durable upholstery of furniture, especially if it has a Teflon coating, so it is not afraid of grease stains. It can be easily washed with a normal household sponge or soft-fleeced brush dipped in soapy water. To clean the microfiber surface of dust, it is enough to vacuum it. Here are the benefits of microfiber in the care: the composition of the fabric allows it to even be washed at no more than 30 degrees without pressing. But if the surface has strong contamination, it is better to contact dry cleaning.

Advantages of innovative material

Microfiber is a fabric that has several advantages:

What is microfiber?

Microfiber is a fabric that looks very impressive and pleasant to the touch. The material was invented in the 90s of the XX century. It is better to dry microfiber products in the air, but not in direct sunlight. Each thread consists of intertwined 50-150 microfibers with a density of less than a gram per 9 km. The villi evenly distribute. The fabric dries quickly, it is not affected by moths and fungi.

Microfiber Care

No fabric combines as many positive properties as microfiber. It is recommended to turn the fabric and articles out of it inside out before washing, and to fasten all buttons and zippers. If you are looking for durable accessories for sleeping, microfiber is a fabric, the bed linen from which will last you a long time. The main thing is not to wash it at too high a temperature, do not dry on hot batteries and do not iron on too hot conditions. This is due to the fact that the basis of microfiber is a polyester thread, and thermal effects can destroy the structure of the fabric.

No fabric combines as many positive properties as microfiber. It is recommended to turn the fabric and articles out of it inside out before washing, and to fasten all buttons and zippers. If you are looking for durable accessories for sleeping, microfiber is a fabric, the bed linen from which will last you a long time. The main thing is not to wash it at too high a temperature, do not dry on hot batteries and do not iron on too hot conditions. This is due to the fact that the basis of microfiber is a polyester thread, and thermal effects can destroy the structure of the fabric.

Microfiber for home

Napkins made of artificial fibers - an environmentally friendly material. With the help of microfiber cloths, you can easily clean any surface, even without using cleaning agents. Enough water and wipes to make your home shine with crystal clarity after a little effort. And even at low temperatures, a wet cloth will dry faster compared to that of cotton. Mirrors, appliances, windows and work surfaces will look perfect, without streaks or lint. Convenient tool significantly reduces cleaning time for the hostess. A microfiber cloth can withstand up to 500 washes. The first 3 times the products may slightly fade, so they are recommended to be washed with products of the same color.

Few people know where microfiber is used and what kind of fabric it is. Most often, it can be found in the form of napkins for cleaning. However, this is not the only application of microfiber. Synthetic material with all the advantages of natural fabrics is used for sewing home textiles, furniture upholstery and outerwear.

Microfiber is a fairly young material, which began to be mass produced in the late 90s. And yet, what kind of fabric - microfiber? It is a dense web, the fibers of which have a thickness of about 0.06 microns. This means that they are 100 times thinner than a human hair. To create such threads, high-precision and expensive equipment is used.

For production use polyester, polyamide or similar synthetic materials. The molten raw material is passed through a special device - an extruder, which by extrusion gives the fibers the necessary shape. The polyester microfiber is then exposed to cold water to separate the raw materials.

The microfibre section has the form of a star, between the ends of which there are other microparticles at a distance. Such a structure provides a large number of gaps, which greatly increases the hygroscopicity and breathability of the material, in comparison with the others.

One thread of 100% microfiber consists of 50-150 smallest fibers. This increases the absorbency of the fabric - it absorbs almost any type of contamination, including water and oil, while not letting it out.

The innovative structure and composition of the material give it a mass of useful properties not inherent in other types of fabric:

There are some disadvantages, but they are insignificant and do not detract from the merits:

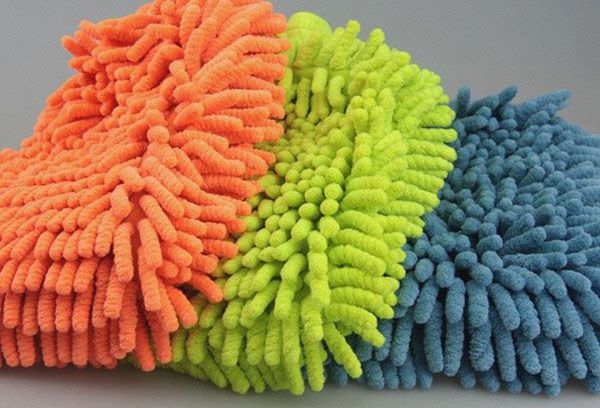

According to the type of material obtained, two main types can be distinguished:

In this case, the density of microfiber may be different, depending on its purpose.

The production of microfibre is currently engaged in three companies, each of which has its own specialization and uses an individual technology:

Due to its unique properties - high density, breathability and hygroscopicity - microfiber has found application in the manufacture of products for various purposes. It received the greatest popularity as fabrics for cleaning.

However, outerwear, underwear and textiles from such a fabric are no less in demand. With all its qualities, microfiber has high strength and durability, which is important for many things.

From microfiber produce:

The material perfectly absorbs pollution, water, does not leave stains. The soft texture does not damage the surface and penetrates into microcracks during cleaning. Static electricity generated during friction polishes furniture and attracts dust particles.

The high density of microfiber allows you to make clothes from it that protects from wind and rain, and also keeps you warm. Fabric does not pass moisture, providing at the same time normal air exchange.

Despite the fact that the material is made of synthetic fibers, it can be used for sewing underwear and children's clothing. Manufacturing technology almost completely eliminates allergic reactions to the fabric.

In fact, any home textile products can be made of microfiber. From it sew bed linen, towels, blankets and pillows. Such things are easily erased and do not crumple. Bedding is breathable, so under them is not hot, but not cold.

High-quality microfiber textiles will not lose their color for a long time, will not stretch and will retain their properties. The main thing is to properly care for the cloth.

The fabric covering of microfiber furniture is durable and unpretentious. To maintain cleanliness, it is sometimes enough to dry it with a sponge or brush. At pollution stains are washed with usual soap solution.

![]()

Microfiber is not subject to abrasion, retains its texture and color for a long time. Spread from microfiber. Such material looks much more expensive than it actually is. And at first glance it is difficult to say whether it is synthetic or not.

The material is quite unpretentious, but there are several mandatory rules of operation:

With proper care, microfiber will last for a long time, maintaining its properties, appearance and shape. It must be remembered that not all synthetics is harmful to health. Technologies for creating artificial fabrics have already reached a new level of quality, and microfiber is proof of that.

It is generally accepted that the properties of synthetic fabrics, in particular, the ability to warm and absorb moisture, are much worse than natural ones. To a certain extent, this was true of the synthetics of the first generation. However, continuous research and introduction of innovative technologies for producing fibers and creating fabrics have proved that some synthetic materials often surpass natural silk, wool and cotton. The microfiber fabric which literally has no equal in the most different spheres of human activity belongs to a new type of textiles. At the same time, what it is, they know not all.

The history of this material has a little more than half a century, and it began with the fact that Japanese researchers were engaged in improving the properties of polyamide fibers obtained by the method of extrusion of the melt. In 1976, the experiments conducted by Toyohiko Hikota and Miyoshi Okamotoy were crowned with success: an ultrathin thread several hundredths micron thick, called microfiber or microfiber, was obtained. However, the first samples of microfibers were rather dense, and were used only for waterproof clothing. Further developments allowed to obtain a fundamentally new structure of microfilaments.

Modern microfiber material includes polyamide and polyester threads. Polyamide fiber under the influence of a special composition is dissected in the longitudinal direction so that its cross section acquires the configuration of an octagonal star. Then polyamide thread is covered with polyester, which is repelled from it, and passed through the spinneret. The result is a fluffy fiber with multiple micropores, due to which the properties of microfiber are unmatched.

The density of such microfiber is only 1 den, that is, 9 km microfilament weighs only 1 g, and its diameter is ten times smaller than that of silk.

The international evaluation of microfiber took place in 1990, at the Swedish exhibition, after which it began to be produced in many countries, primarily in the United States.

Finding out the question of what microfiber is good for and what kind of fabric it is, it is necessary to take into account that many different materials are made from microfibres, including those with the addition of natural raw materials and viscose. The most famous of these is the tactel. It was created by specialists of the DuPont concern on the basis of polyamide fibers, as well as fabrics, which are its varieties:

Especially distinguish the micromodal material, which includes cellulose obtained by processing beech wood. Micromodal in appearance and tactile sensations resembles silk, but has a higher breathability, ability to absorb moisture and regulate the level of heat at the surface of the skin.

There is also a microfiber with special coatings, such as Teflon, which makes it waterproof and resistant to dirt.

Due to the nature of the structure of its fibers, the microfiber material has unique characteristics associated with the fineness and porous structure of its filaments. The main properties of microfiber are as follows:

Due to the nature of the structure of its fibers, the microfiber material has unique characteristics associated with the fineness and porous structure of its filaments. The main properties of microfiber are as follows:

However, these fabrics have certain disadvantages. First of all, they can accumulate a static charge, which produces discomfort when touched, and also contributes to the surface attracting villi, dust and other small particles. It should also be remembered that polyamide does not tolerate high temperatures. Sophisticated production technology causes the high cost of microfiber compared with other synthetic materials, although most of its varieties are quite accessible to the ordinary buyer. Microfiber made in China can be inexpensive, but its quality and durability are unlikely to be high.

Everyone knows a variety of diverse microfiber clothing, which is well suited for very young children. The variety of types and textures of microfiber materials makes it possible to use them for beautiful linen, swimsuits, thin summer T-shirts and dresses, tight sportswear, sweaters, warm linings for outerwear, including for polar jackets, etc. Very common is microfiber bedding, which can be as beautiful and elegant as silk or cotton, but at the same time it is cheaper, it retains its beautiful appearance for a long time and does not require additional efforts when washing and ironing.

Equally popular is microfiber as a home textile. They make plaids, bedspreads, blankets, rugs and even furniture upholstery. Speaking about the household, we should not forget about such things as cleaning cloths and mops from this material. The porous structure of the fibers absorbs all contaminants, both dry microparticles and liquids, and often allows you to do without cleaning preparations.

Thanks to its absorbing abilities, microfiber is contaminated very quickly and requires regular cleaning - with both a vacuum cleaner and water with detergents. Microfibre belongs to a small group of materials for which machine wash is preferable to hand washing. This is due to the fact that in a washing machine, dirt that has penetrated deep into the fibers is removed more efficiently, and after machine spinning, the product becomes almost dry and dries instantly.

For washing, you need to use water not hotter than 60 degrees, you should not use air conditioners. It is also undesirable to dry microfiber items near heat sources and iron them.

Progress does not stand still. Every day, the best minds invent new technologies and make discoveries in all spheres of life. Natural fabrics are quite expensive or do not always meet the increased demands of modern life. Synthetic industry is not always harmful. Scientists were able to develop a fiber that has high strength and moisture absorption. His name is microfiber (microfiber).

Microfiber is an extremely thin fiber, which is ten times smaller than a human hair. The prefix of this word speaks about the small size. The diameter of the fiber is 0.06 microns. Undoubtedly, for its production requires high-tech equipment.

The origin of microfiber is Japan. Back in the 70s of the last century, scientists mastered the production of this material. This was a breakthrough in the textile industry. Due to the properties of the fiber, its fame quickly spread throughout the world. Production volumes had to be increased many times. This was undoubtedly a success.

However, initially, microfiber products were much thicker than they are now. The breakthrough occurred in the early 90s, when scientists from Sweden were able to split the thread 8 more times.

What is microfiber? What is it made of?

The basis of this thread is polyester and polyamide. If you view the fiber at high magnification, you can see the grooves. This design absorbs moisture well and provides the best performance to microfiber products.

The quality of the final microfiber product depends on the number of nodes and splittings in its thread. The more of them, the higher will be the characteristics of the product.

The type of splitting affects the final characteristics. The smaller the thickness of the sector, the softer and more tender the fabric will be. Interacting with specialists receive characteristics that are applicable to a particular product, depending on its purpose.

Depending on the components that make up the composition, the final type and orientation, there are several types of microfibre-based fabrics:

Let's talk about each form in more detail.

This fiber is made from cellulose derived from beech. It is distinguished by subtlety, softness and durability. Even with prolonged use, it does not lose its elasticity and original appearance. Feels like products made from this fiber look like silk. They are soft and velvety.

Such qualities like air permeability and hygroscopicity, allow to use it for the manufacture of clothing and bedding. According to its characteristics Micro Modal® wins cotton, and several times. TO undoubted advantages include:

The Tactel® trademark combines several categories of fabrics with different characteristics, based on polyamide microfibers. Products of this brand saw the light in 1983 in the USA. Products from these fibers create the effect of "second skin". They are very gentle, comfortable and soft. Combining the fibers with each other, the specialists of the company released several modifications that meet different requirements.

Main tactel® micro is thin. From these fibers, you can create the most delicate knitwear. In this case, all products prevent wetting and blowing.

Tactel® multisoft focuses more on linen products. These fibers have a special form of weave, which gives elasticity and softness.

The glow of fabrics and things from Tactel® Diablo does not compare with anything. This was made possible thanks to the special weaving of fibers. They give the products a soft glow and overflow.

The advantages are also easy to care. Products dry quickly and do not crumple.

Tactel® stratum allows you to create fabrics with the effect of "melange".

This is achieved through the use of threads of different sections. The category Tactel® aquator is created for the manufacture of "breathing" things. They dry quickly and are erased. The climate of Tactel® is very comfortable and pleasant to the body. Appearance depends on the characteristics and structure of the fibers. You can create as a streaming product, and with the effect of "velvet".

Taktel® Texture allows you to create things that look coarse, but soft to the touch.

All Tactel® fiber products are durable, aesthetic and durable. They meet the highest standards. Tactel® fibers have already been dubbed the “21st Century Cotton”. In combination with other materials can achieve unprecedented results and characteristics.

MERYL® fiber fabric is no different in appearance from its natural counterparts, but surpasses them in characteristics and properties. Even underwear is made from it. Despite the fact that synthetic fabric is obtained, this does not affect the human sensations.

She "breathes" and does not cause any discomfort. In addition, MERYL® fiber products possess antiseptic properties as they are treated with silver ions.

They do not crumple. The only thing that can scare away is the high price. But it will pay off in the process of wearing and use. The basis of MERYL® is polyamide microfiber.

The diameter of the fibers is very small, therefore, high-tech and high-precision equipment is used to manufacture microfiber. Only with the help of it you can achieve the required thickness of the thread. The components of microfiber, polyester and polyamide are prepared in advance. Polyamide yarns give a cut shape. The polyester is melted and the second necessary component is added to it.

Only after this components are placed in an extruder. This machine softens the materials and gives them the necessary shape. This is achieved by pushing through special filter holes (extrusion heads). They allow you to create a section according to predetermined parameters. But this production technology is not yet complete.

The second step is to separate the polyamide yarn from the polyester. To this end, the thread is cooled with water. This contributes to the creation of a large number of micro gaps, which provide such high performance to microfiber products.

Like any material microfiber has its advantages and disadvantages.

There are few disadvantages, but they are still present:

As you can see, although there are disadvantages, they overlap with many advantages. Microfiber is a synthetic material, but do not be afraid of it.

Who says that it is impossible to sleep, is deeply mistaken. This is an innovative material that is not inferior in performance to cotton and silk. With a number of positive characteristics, microfiber is able to make your sleep comfortable.

Bed linen from this material is produced by factories of different countries: Russia, France, USA, Germany, China. But when choosing do not flatter yourself for a low price - real microfiber can't be cheap.

Microfibre blankets and blankets are widespread. Under them is not cold in winter and not hot in summer. They are warm, cozy and soft. Easy to wash and do not require ironing.

Clothing has also become popular lately. It is durable and not subject to deformation. Products from this material recommended even for babies, and it says a lot. Depending on the weaving and thickness of the threads, you can achieve the effect of velvet, cotton or canvas. According to your inner feelings, you would never guess that it is synthetic, and not natural material.

Microfiber products are undemanding in care and operation, but still there are times that need to be paid attention to.

If you bought bed linen or a microfiber blanket, then the first thing is to wash it. This will eliminate dust, fibers that could get to the surface during storage or transportation. You can wash in the car at a temperature not higher than 60 degrees.

How to care

It is better not to expose microfiber products to boiling and exposure to chemicals. When washing it is better not to use fabric softener. Also pay attention to the detergent - it is better that it is neutral.

When washing, turn inside out, fasten buttons, buttons or lightning. Do not use bleaching compounds. Drying is best done in natural conditions. It is possible to iron only on the “silk” mode, but it is better to refuse this item altogether - the products practically do not wrinkle.

It is necessary to take into account the fact that when drying on the battery, the products can be deformed.

By following these simple tips, you can enjoy your purchase for a long time, keeping it intact.

When choosing microfiber products, you should pay attention to the following factors:

| Related articles: | |

|

Microfiber what kind of fabric: properties and composition

Material: technology and production Microfiber or microfiber - fabric, ... How to remember a large amount of information: quickly and for long

Almost every person in his life faced such a task ... Creamy champignon soup: classic and originality

No ideas on cooking for lunch? In this case, you can ... | |